House Foods America is a tofu manufacturer that has achieved GFSI-recognised certification with SQF. Recently, members of GFSI’s Japan Local Group conducted an interview with House Foods America representative Rina Yamada to discuss the company’s journey to GFSI-recognised certification and how they “aim to foster an unwavering food safety culture by allowing each employee to continue to work on improvement with a devoted attitude.”

GFSI Japan Local Group Communication WG (GFSI): First of all, please introduce your business, including your characteristics.

House Foods America (HFA): We are a group company of the House Food Group and operate a tofu business in the United States. The group mainly develops curry and spices in Japan. We couldn’t enter the tofu business in Japan while considering various new businesses in the past because there was a barrier to the small and medium-sized enterprise field adjustment method. Therefore, we decided to expand our tofu business in the United States and invested in a Japanese tofu company in Los Angeles (LA). In 1993, we acquired 100% of the company’s shares at the time of the owner’s retirement, changed the company name to HFA, and started the business.

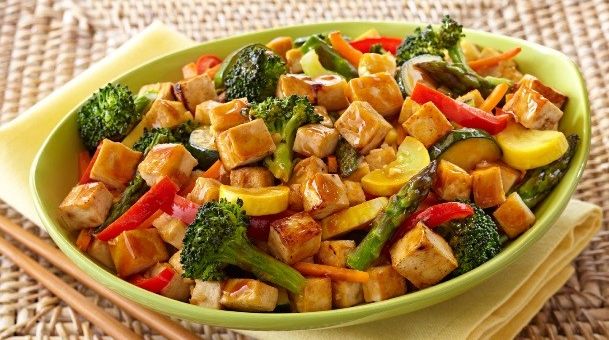

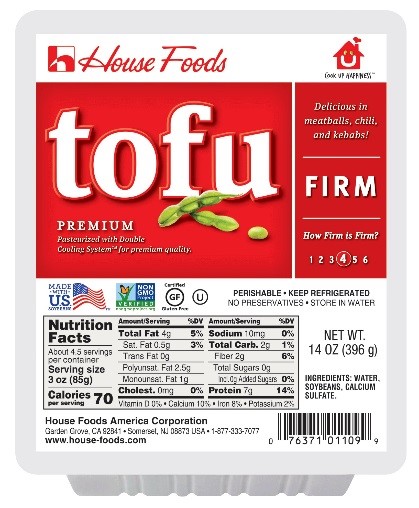

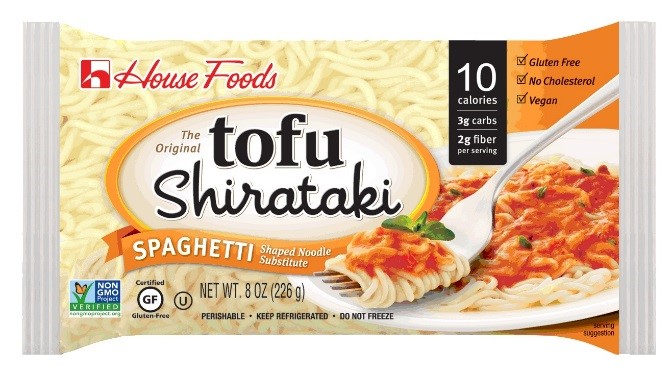

Currently, the two manufacturing sites are in LA and New Jersey (NJ), covering the entire United States and Canada, and exporting some to Europe. We used 100% US-made, non-genetically modified soybeans. Approximately 70 tons of soybeans are used and production is performed 24 hours a day at two factories. In the United States, tofu is often stir-fried rather than eaten raw, and firmer tofu is preferred. Therefore, we have a product lineup with six levels of firmness. The packaging form is the same as in Japan, but there is a shelf life of 65 days in cold storage because of the sterilisation process. In addition, a product called Tofu Shirataki, which is kneaded with konjac tofu, has been selling well as a low-calorie noodle substitute along with the healthy food boom. Currently, as a proposal for new ways to eat, we have developed products which are sold as a set with ramen soup and stir-fried seasonings.

Initially we targeted the Asian market but the growth of the U.S. market and commercial products have been significantly increasing due to the trend of plant-based protein and the increase of vegans. Thus, the sales ratio is exceeding the those of Asian market.

GFSI: Could you tell us how you worked to obtain SQF certification?

HFA: Around 2012, there was a request from a major U.S. retailer, and as a prerequisite for future transactions, we had to take action to obtain SQF certification the following year. At that time, although our company had a HACCP+GMP system, the management system was not established. But we obtained SQF certification at the LA plant in 2014 and the NJ plant in 2016.

GFSI: How did you promote SQF certification and what was the difficulty in developing it?

HFA: SQF is a company-wide system involving top management. Without the culture of building and operating a management system, it was hard to build the system according to the actual situation, especially as we had difficulty promoting understanding for employees who did not understand the benefits of acquiring the certification. In addition, there were technical challenges. “Tofu Shirataki” is an alkaline food, but there were no similar food categories or applicable public standards. So it was very difficult to consolidate food safety backdata in the short-term schedule.

GFSI: Could you tell us about the benefits of working on SQF certification?

HFA: Since the internal advantage of “continuous improvement” — which is the essence of management systems such as SQF — was achieved production troubles have been reduced. In the two years after obtaining certification, we were not able to get out of the original situation

First of all, the leaders of each department appointed as internal auditors were able to understand the requirements and realise that the current system was built on the requirements. As a result, the internal audit exceptions were getting more and more severe, and the questions became essential. I feel that we have developed a sense of improvement. Also, there was a strong awareness that audits can be managed, and audit response was left to the quality control department at the beginning of obtaining certification. But the manufacturing department is now taking the initiative to respond. I feel that the number of conversations about food safety is increasing on a daily basis, and awareness has been fostered. As a result, the continuous improvement has progressed little by little.

GFSI: Various improvements are being made. Could you tell us more about what you would like to strengthen in the future?

HFA: There are still many things to do to ensure continuous improvement, but I would like to strengthen the education for leaders of the manufacturing department in particular. After all, it is necessary for the leaders and operators of the manufacturing department to understand the meaning of important points related to quality and food safety, and to have them acquire correct knowledge. If you just say “don’t do this” or “do this,” they may not be able to cope with unusual things. The accuracy of the information raised to the quality control department isn’t high. In addition, what the leaders learn has a positive effect on the operators.

GFSI: Are there any differences in Japan and the United States regarding food safety? Can you tell us if there are any things that you are careful about?

HFA: We have employees from different races. Most people, including myself, are not native English speakers, and the cultural backgrounds are different. Therefore, it is necessary to pay considerable attention to the thoroughness of instruction, communication, and information sharing unlike in Japan. It is completely different from Japan, where non-verbal communication works in the high context culture. In such an environment, the smartphone is an effective tool. Leaders use smartphones to quickly share what’s happening in the field with images, videos, and texts. For example, if you have trouble, you can immediately share that information with videos and images, and if you find a point that is not organised enough, you can point out the relevant information with photos. It is also useful to share the results of quality confirmation for each process and quickly give instructions so that you can proceed to the next step. We may mishear or misunderstand things with verbal instructions, but we can be sure to tell with texts or images. In addition, it is clear who is giving instructions, what needs to be done and how, and the taken actions can be shared.

Moreover, safety of the employees is the most important reason to be cautious at the plants. There are various production facilities, so if you make a mistake in handling them, it can lead to an accident. The NJ plant holds weekly safety meetings to ensure that employees are always aware of safety. Again, when we use smartphones to find dangerous places or actions, we share photos and videos from our smartphones on to large monitors, and immediately prevent recurrence and improve the content.

GFSI: Finally, could you tell us about your future prospects, as to how SQF will be utilised in the future?

HFA: SQF is a tool. We believe that improvement will accelerate even more if we can make full use of this tool, make further

(GFSI) Thank you to everyone at House Foods America.

Subscribe to GFSI News