The Future of Food Safety & Quality is NOW

Why Food Safety Needs a Smarter Approach

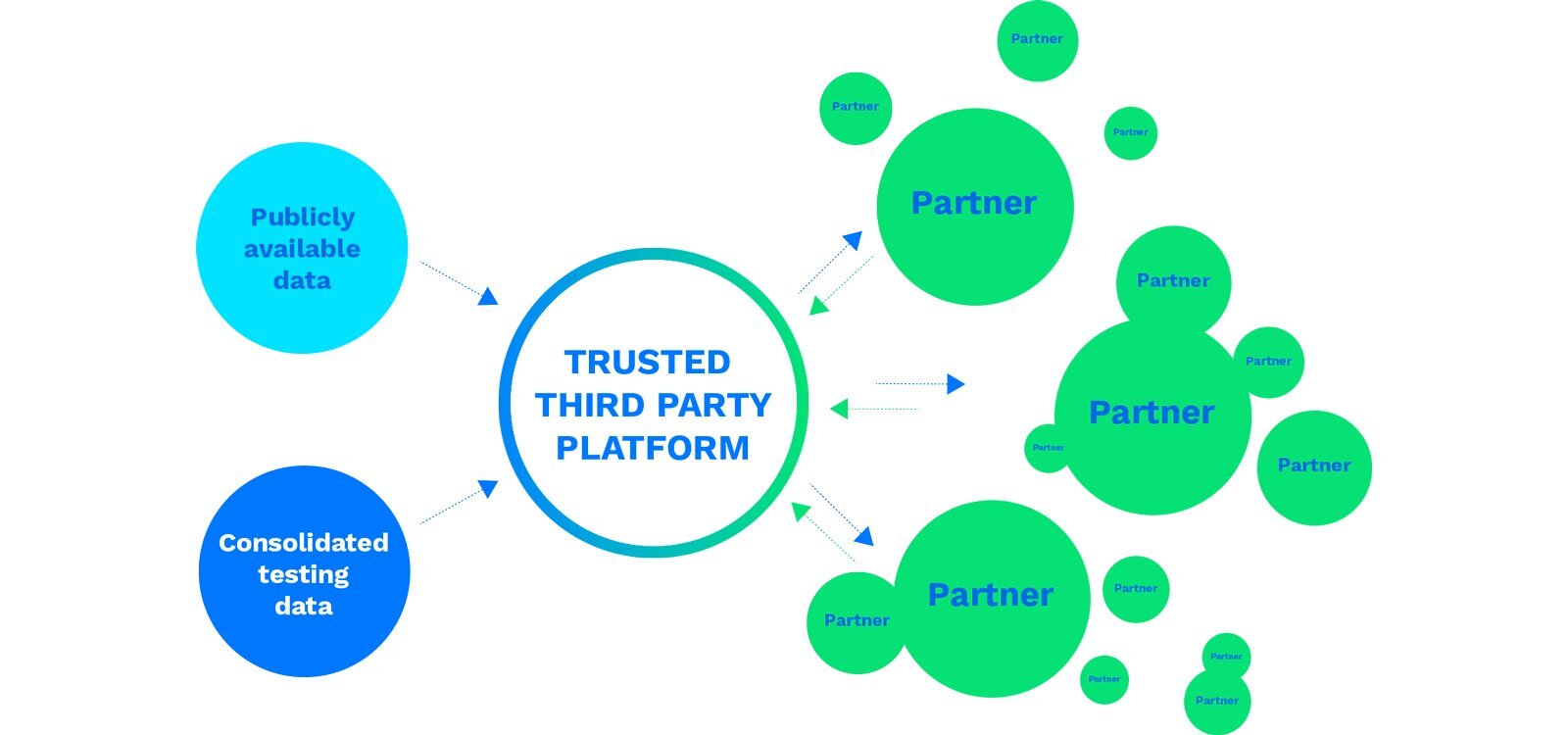

Food safety is a dynamic challenge. New risks emerge, regulations evolve, and supply chains grow more complex. Yet, the way we manage food safety remains largely unchanged, relying on traditional risk assessments, testing, audits, and fragmented data sources. As no single company has the full picture, what if food manufacturers and suppliers could pool their data in a structured and secure way? This is what the Trusted Third-Party model enables—a method to share testing data, understand the evolution of risks over time, benchmark against industry peers, and anticipate risks before they become costly problems.

From Reactive to Proactive: The Power of Data-Driven Risk Management

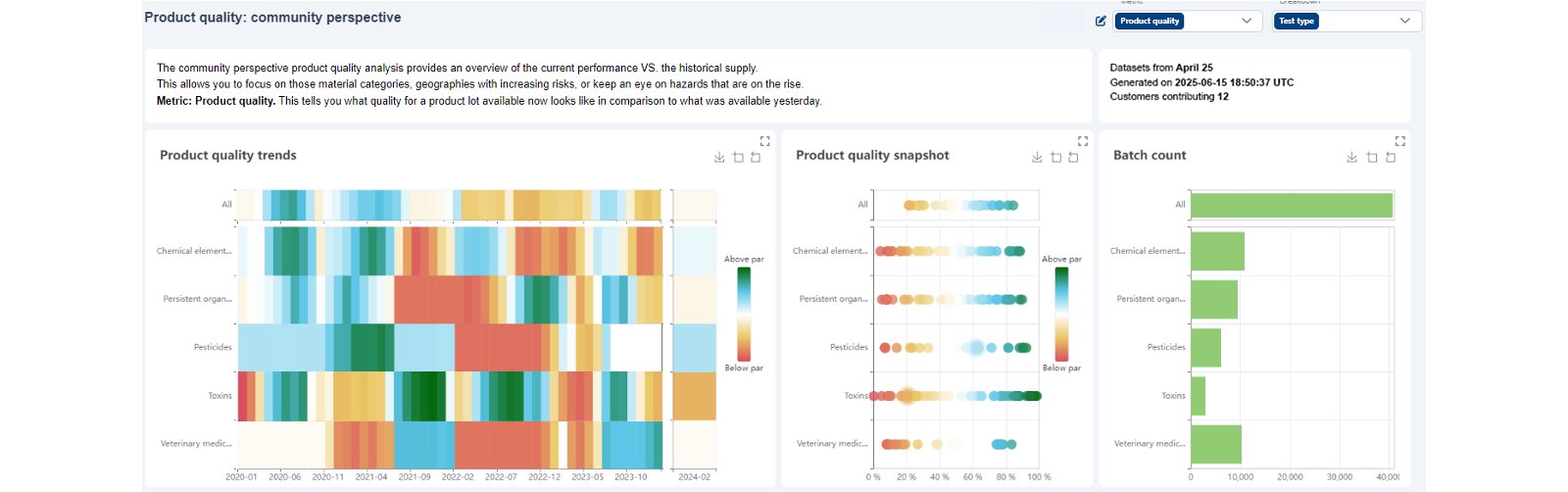

Food safety has traditionally been reactive, responding to problems with more testing or audits. This approach is no longer enough. The Trusted Third-Party model shifts the industry toward proactive risk management. By using real-time data and cause-and-effect modeling, companies can anticipate risks. For example, instead of waiting for aflatoxin levels to spike, companies can spot seasonal trends, storage conditions and transportation hazards and adjust their testing programs in advance. They can engage suppliers earlier, collaborating to prevent contamination rather than just reacting to it.

The Cost of Getting Food Safety Wrong

Supply chain risks are costly. A single recall can lead to millions in lost product, reputational damage, regulatory fines, and legal consequences. Production disruptions add to this burden, especially when factories operate at full capacity with little margin for error. Many companies have shifted from Just-In-Time (JIT) inventory strategies to Just-In-Case (JIC) approaches, building safety buyers into supply chains. While this helps manage risk, it also increases costs. The key challenge is balancing cost reduction with risk management, and this is where data-driven collaboration truly makes a difference.

By leveraging the Trusted Third-Party model, companies can identify vulnerabilities before they cause failures. They can assess whether raw material specifications are realistic based on historical data or if emerging trends suggest a need for greater vigilance.

Bringing the Trusted Third-Party Model into Business Operations

The Trusted Third-Party model allows companies to share lab-agnostic testing data in a secure, anonymized environment, offering a broader, more detailed view of risk. Participants contribute data in a way that suits them and, in return, gain access to valuable insights, enabling them to benchmark their supply chain against industry standards, track historical trends, and identify emerging threats in specific commodities, regions, or contaminants. This model acts as a data hub, harmonizing information from contributors and public sources to provide actionable insights, which help businesses refine their risk management strategies, optimize testing programs, and enhance supplier oversight. Beyond safety, the model enables smarter business decisions, supporting procurement strategies and regulatory compliance by streamlining submissions with pre-analyzed, anonymized data.

Built on trust and confidentiality, it ensures that insights cannot be traced back to individual suppliers while providing measurable value through a fact-based, real-time understanding of risks. This approach enhances decision-making, strengthens supplier relationships, and fosters a proactive, collaborative effort to protect food safety across the industry.

The Future of Food Safety: a Collaborative Effort

Food safety cannot be managed in isolation. The risks we face—whether they are linked to chemical contaminants, supply chain disruptions, or new regulations—demand a more connected approach. By participating in the Trusted Third-Party model, companies gain the insights they need to stay ahead of risks, optimize testing, and ensure resilience. In an industry where one weak link impacts everyone, the best way to protect supply chains is through secure, intelligent and proactive collaboration.

Mérieux NutriSciences & bioMérieux