Seattle is a city where many global mega corporations started their businesses. For this year’s GFSI Conference, a Discovery Tour was planned and held in Seattle, in partnership with three famous companies. I am here to recap the Discovery Tour, which took place the day before the Conference and included visits to Costco, Amazon and Starbucks!

Costco Wet & Dry Delivery Center

Costco, a warehouse-type store, has a business model focused on returning most of the profits to member customers by keeping product margins very low, at 8-14%, while earning most of their revenue from their membership fees. In order to keep margins as low as possible, various measures to reduce costs are also implemented at distribution centers. For example, a custom-built forklift made exclusively for Costco has a very long lift handle and can carry five pallets simultaneously. Speed is very important because a large amount of goods are purchased and moved. The mechanism is built to complete the transfer to the shipping truck in about 2 hours from the arrival of the goods. An inventory management system using RFID (Radio Frequency Identification) has been introduced to allocate cargo to destinations numbered from 1 to 50.By reading the tag (RFID) containing the chip with a reader, the destination in the warehouse is automatically instructed, so that the person in charge does not get lost.

Cargo is more expensive than the cost of labour. Thus, the machine automatically simulates the layout of the cargo so as to minimise the waste of space and allocates it. The person in charge should follow instructions instead of making a decision on their own, so there is no mistake in making the decision. By avoiding waste in this way, it is possible to receive, move and ship large quantities of goods in a short time. They have also reducing costs by changing the material of pallets from wood to plastic. Although it costs more money, about $50 to $80 each, plastic lasts longer than wood. In addition, plastic is lighter than wood, so the weight of the item to be lifted will increase.

In terms of quality control, a dedicated building is prepared for quality inspection, especially for fresh products. The floor in the warehouse is cleaned daily, and insect control is managed by a third-party organisation. The number of employees working in the warehouse is about 450, and the employees work in shifts 10 hours a day from Monday to Friday. Because the salary is set relatively high and employees receive other benefits, the job retention rate is good; the turnover rate is less than 2%.

Amazon Go & Spheres

Over 40,000 plants are planted throughout the office, just as if it were an office in the Amazon. The concept of this office is to increase relaxation through the use of many plants and

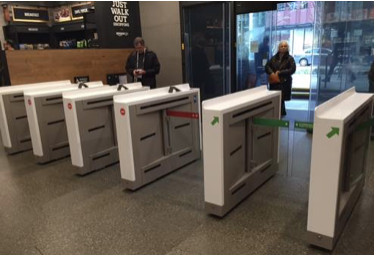

Amazon Go Store

The defining feature of the Amazon Go store, which currently operates in four cities across the USA (Chicago, New York,

Starbucks Kitchen

The bread industry requires a lot of labour from early morning until late at night, but mass production has been achieved by introducing machines that can mold the dough into the desired shape. Delivering the dough made in the central kitchen to stores and baking them in-store is

The 2020 Discovery Tour was a very meaningful tour that lead to a better understanding of three companies that originally started in Seattle. Thank you very much to everyone who spent their time organising and guiding the tour.

This post was written and contributed by:

Yuriko Shirasu

GFSI Japan Local Group Communication WG

Quality Assurance Division

Kewpie Corporation